“`html

MP Materials has commenced commercial production of neodymium-praseodymium (NdPr) metal and trial production of automotive-grade neodymium-iron-boron (NdFeB) magnets at its Independence facility in Fort Worth, TX, set for late 2024. This marks the first U.S. integrated mine-to-magnet supply chain in decades, essential for electric vehicles and advanced technologies. The company reported first-quarter revenues of $5.1 million and second-quarter revenues of $19.9 million in the Magnetics segment, driven by sales to General Motors (GM) as part of a long-term agreement.

MP Materials has received prepayments totaling $150 million from GM, which is currently its only customer for magnetic precursor products. The facility aims to manufacture approximately 1,000 metric tons of NdFeB magnets annually by the end of 2025 and is planning expansions to reach a capacity of 10,000 metric tons to serve both defense and commercial sectors. In July 2023, MP Materials entered into a partnership with the Department of Defense to strengthen the U.S. rare earth magnet supply chain.

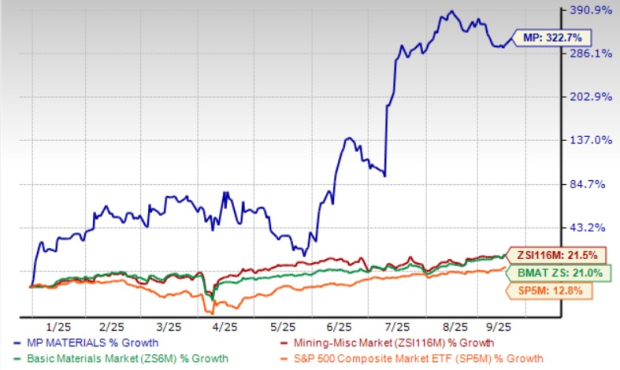

Additionally, the company announced a long-term agreement with Apple to supply rare earth magnets made from recycled materials. This collaboration aligns with efforts to create sustainable supply chains. MP Materials’ shares have surged by 322.7% year-to-date, significantly outperforming the industry growth of 21.5%.

“`